Novel Technologies That May Signal The End Of The E-Waste Problem

Photo Credit: iStock/Petmal

We have talked at length about the devastating effects of electronic waste on human, animal, and planet life. These effects are deep rooted and multibranched.

But since this is our 2022 wrap piece, we want to end the year on a hopeful note.

So, today we are going to highlight some of the most innovative, novel, and creative technological advances that, if implemented on scale, could signal the beginning of the end of electronic waste as we know it.

These technologies include everything from artificial intelligence, to robotics, to bio sorbents and more.

What makes these technologies so much more promising is how the best minds in the world are combining them — instead of focusing on each as a separate solution to the problem — and creating software programs and businesses to make them more mainstream and applicable.

Here they are.

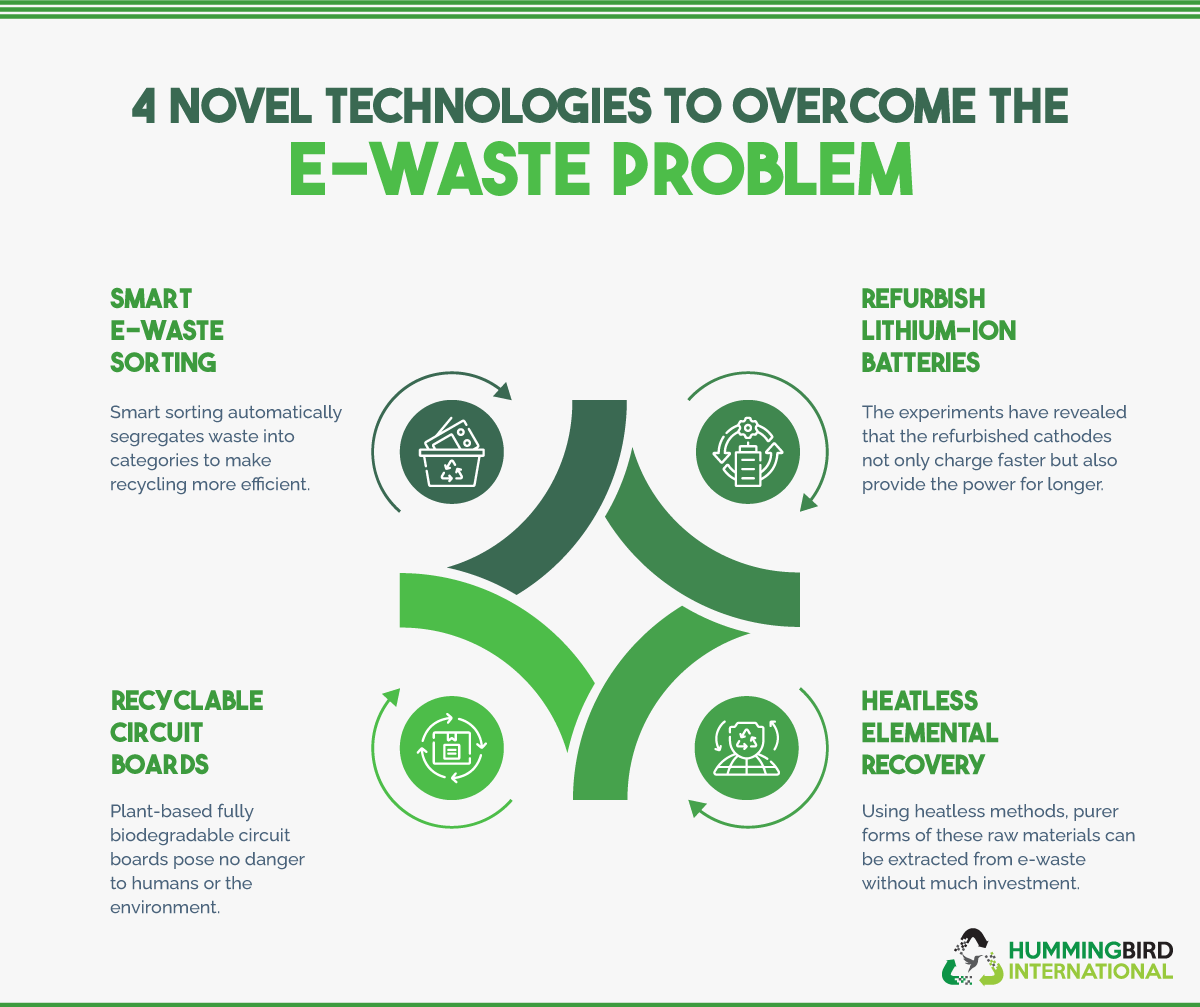

• SMART SORTING

Image Source: iStock/Moyo Studio

The Problem It Solves:

ICTs are a large stream of e-waste because they use a tremendous amount of materials to manufacture various electrical and electronics products. A huge reason recycling often fails is that separating valuables from useless materials is often dangerous, requires too much time, and may not always be accurate.

Smart sorting automatically segregates waste into categories to make recycling more efficient.

How It Solves The E-Waste Problem?

Automatic sorters use artificial intelligence, machine learning, robotics, sensors, and intelligent data processing to identify products in e-waste that can be reused, recycled, or refurbished.

Things that can be reused after a bit of repair and polishing are segregated so they can be fixed and sent out into the world again. Things that cannot be salvaged go into the next phase where smart machines break them open to get to the (good) raw parts.

Valuable elements such as gold, platinum, palladium, and others like silver and copper are identified and separated. Plastics and other materials that cannot be reused are sent for recycling.

Using these technologies, companies like Tomra, ensure e-waste disposal work takes less time to finish, sorting becomes more accurate, and any potential health hazards to humans are taken out of the equation.

• REFURBISHING THE CATHODE IN LITHIUM-ION BATTERIES

Image Source: iStock/Aranga87

The Problem It Solves:

Extraction of lithium becomes increasingly dangerous every day. The mines in many countries are running dry, establishing new mines is dangerous for communities living in the area, and even the mines that are working currently usually use child labor in their operations.

How It Solves The E-Waste Problem?

So, when our batteries go dead, it’s because the current that flows from one end of the lithium-ion battery (anode) to the other end (cathode) cannot do so anymore because the cathode has lost the critical levels of lithium it needed to charge the battery.

Researchers in Princeton University have created a novel way where they inject the needed amounts of lithium back into old cathodes and make them brand new. (If you are interested in the science of it, here’s an article by researchers that explains the process). Battery manufacturers were not sure if the recycled cathodes were reliable or safe. But the experiments have revealed that the refurbished cathodes not only charge faster but also provide the power for longer. Sustainable use of available lithium ensures that other elements in the batteries don’t have to go to landfills and instead can be used in new batteries again. Meaning, a longer life for battery as well as for the device.

• BIODEGRADABLE CIRCUIT BOARDS

Image Source: iStock/krystiannawrocki

The Problem It Solves:

Present circuit boards are not made to biodegrade. Most of them go directly to landfills. There, they release toxins to earth, water, and air. Even when recycled, the separation of metals requires incineration, which produces toxic gasses. If you use acid, you are left with large quantities of acidic water that will again go to waste.

Researchers have now successfully created plant-based fully biodegradable circuit boards that pose no danger to humans or the environment.

made with paper, silicon, and other biodegradable materials.

How It Solves The E-Waste Problem?

Traditional printed circuit boards (PCBs) are made of fiberglass, copper, and epoxy — elements that are difficult to recycle.

Researchers, from various parts of the world, have been successful in creating biodegradable circuit boards made from silicone, paper, cellulose from banana plants, and more, which make the entire board more friendly to the environment. These boards, after they have finished their lifecycle, can be dissolved into water, lit and consumed by fire, and given back to earth to be absorbed by nature again.

All these circuit boards have been proven to show high levels of strength and performance under increased levels of humidity and temperature. It translates to an electronic device with a reliable circuit and powerful circuit board that will be a friend to the environment as well.

• HEATLESS ELEMENTAL RECOVERY

Image Source: iStock/Estradaanton

The Problem It Solves:

Precious metals are some of the most valuable parts of electronic devices. These include gold, platinum, palladium, and more. When these products are thrown to waste, these elements need to be separated from surfaces so they can be used again. Current detachment methods use heat to do the job. But it causes toxic gasses, costs a lot, produces dust, and requires large amounts of energy and pressure.

Using heatless methods, purer forms of these raw materials can be extracted from e-waste without costing a lot of money or incurring environmental damage.

How It Solves The E-Waste Problem?

E-waste items (circuit boards, jack connectors, and more) that contain precious metals are dissolved using acidic mixtures. In the solution, different other chemicals are added to ensure an optimum level of leaching of precious metals.

Once the solution is at room temperature, ascorbic acid is added to the mix which separates precious metals from the solution. These metals have been noted to have high levels of purity, up to 90%, which can be even more refined using a thermal refining process.

Since the process doesn’t use intense amounts of energy, there is no fumes, gasses, or dust to contend with. The leaching process gives you pure chemicals, and have been proven to be a viable recycling business by companies such as Jason Matthey.

E-wastes that contain these precious metals, such as circuit boards, jack connectors, and more, are dissolved with acid mixtures. This liquid is then mixed with other chemicals to ensure optimum levels of leaching of precious metals.

What does it mean?

It means that, sure, we still have a long way to go, but the e-waste problems at hand must not deter us from celebrating the wins we have been gaining along the way.

The most brilliant minds in the world have been working tirelessly to perfect advancing, novel technologies that are addressing the waste crisis more proactively, with a preventive mindset.

While we still have roads to travel, it’s good to see how far we have come. Let that knowledge fuel our passion as we continue to create a cleaner and greener earth.

About The Author Kelly Sampson

Kelly Sampson is a writer, blogger, and environmental enthusiast. She has strong opinions about climate change, the dogs vs. cats debate, and Oxford commas. She has lent Hummingbird International her engaging and spirited voice and turned our blog into a great place to find valuable information about e-waste, e-waste recycling, and the ITAD industry. Explore our blog to read more of her work.