- What is the E-waste Problem?

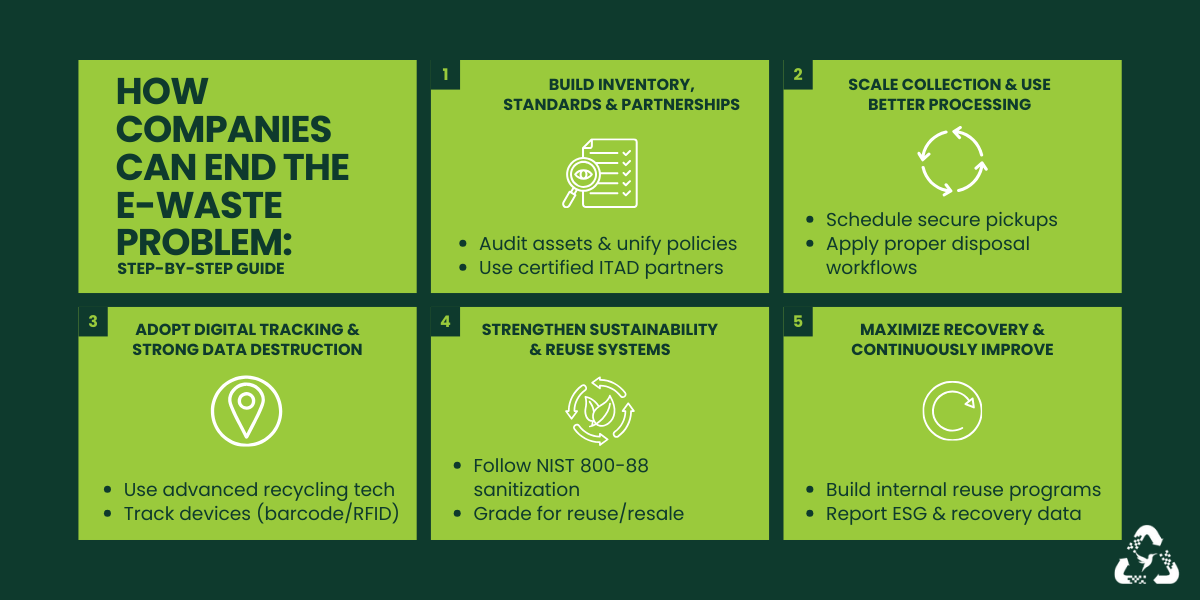

- How Companies Can End the E-Waste Problem: Step-by-Step Guide

- Step 1: Build an Inventory, Standards and Partnerships

- Step 2: Scale Collection and Introduce Advanced Processing Options

- Step 3: Adopt Digital Tracking, Advanced Data Destruction and Cost Optimization

- Step 4: Strengthen Sustainability Reporting

- Step 5: Maximize Recovery and Maintain Continuous Improvement

- Case Study

- Case Study 2

- Case Study 3

- E-waste as a Green Economy Opportunity

- 4 Ways to Build a Circular, High-Value E-Waste System

- FAQs

- 1. What is the single most effective way to reduce e-waste at scale?

- 2. Why does illegal export remain such a major barrier to ending e-waste?

- 3. How can businesses directly help end the e-waste problem?

- 4. What role does technology play in solving the global e-waste crisis?

- 5. Does solving e-waste really create jobs and economic benefits?

What is the E-waste Problem?

This refers to the growing environmental and health crisis caused by the improper disposal of electronic waste. In 2022, a record 62 million tonnes of electronic waste was generated which was around 7.8 kg per person worldwide. Out of this, only 22.3% was formally collected and disposed of sustainably. If this continues, e-waste could reach roughly 82 million tonnes by 2030.

The increase in e-waste outpaces recycling capacity for now. So it means that more toxic materials will leak into ecosystems and human communities.

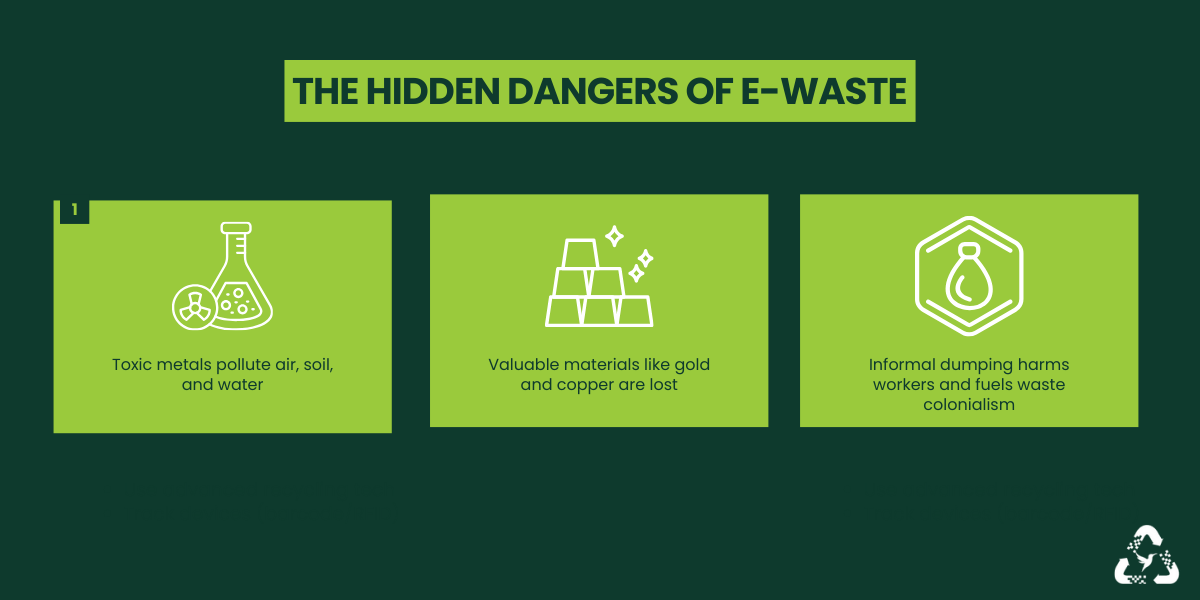

E-waste has three major risks:

- Environmental/health: devices contain lead, mercury, cadmium, flame retardants and other toxics that contaminate soil, water and air when improperly handled.

- Resource waste: electronics hold gold, silver, palladium, copper, rare earth elements that lose their value.

- Security and social: informal recycling exposes vulnerable workers to hazards. It also leads to ‘waste colonialism’ where high-income countries ship e-waste that ends up polluting low-income regions.

Policies to Manage the E-waste Problem

Extended Producer Responsibility (EPR) is the most important policy for shifting responsibility and revenue to manufacturers. This means producers have to handle the cost and operational responsibility for collection, treatment and safe disposal of electronics.

Well-designed EPR programs drive:

- Collection systems (take-back, drop-off, retailer collection)

- Funding for recycling infrastructure and collection logistics

- Design incentives, including the fees that reward easier-to-recycle products

- Reporting and traceability requirements

Without clear reporting, auditing, and incentives, EPR may not be as effective. To reduce or manage the e-waste problem, EPR needs data frameworks, variable fees that reward repairability/recyclability, and strong implementation.

Effective EPR Policy

| EPR Element | Description | Why It’s Critical |

|

Clear Producer Responsibility |

Producers (not consumers or municipalities) fund and manage end-of-life collection, recycling, and safe disposal | Makes sure the financial burden shifts upstream and creates accountability |

|

Variable / Modulated Fees |

Eco-modulated fees reward products that are easier to recycle or repair, and penalize hard-to-recycle designs. | Drives eco-design, reducing future waste at the source |

|

Mandatory National Producer Registry |

All producers must register and report sales, collection volumes, and recycling outcomes | Eliminates free riders and creates transparent data for enforcement |

|

Collection & Take-Back Requirements |

Producers must provide accessible collection systems (retail drop-off, mail-back, enterprise pickup) | Maximizes collection rates and prevents illegal dumping |

|

Audited Reporting & Traceability |

Third-party audits verify quantities collected, treated, reused, and recycled | Prevents fraud, data manipulation, and export leakage |

|

Reuse & Recycling Targets |

Legally binding national targets for reuse, repair, and material recovery | Ensures measurable progress instead of voluntary commitments. |

|

Local Recycling Infrastructure Support |

Funds, grants, or incentives from producer fees support domestic recycling facilities | Strengthens domestic circular economy and reduces export dependence |

|

Enforcement & Penalties |

Non-compliant producers face fines, sales restrictions, or loss of market access | Creates real consequences and keeps the system functional |

Role of Businesses in Cutting Down E-Waste

Businesses that integrate lifecycle thinking, procurement, product design, take-back and refurbishing, reduce costs and risks greatly.

Concrete actions companies can adopt today:

- Design for disassembly and repair – modular phones and removable batteries make refurbishment viable and reduce material loss

- Corporate take-back and resale programs – retailers and OEMs can resell refurbished devices, capture value and extend product life cycles

- Procurement policies – require suppliers to meet recyclability and repairability scores

- Use certified ITAD partners – R2v3/e-Stewards + NAID for data security

It is important to keep in mind that concrete incentives, not just regulation, will speed adoption.

Technological Innovations to End E-waste

Recent upgrades in technology are responsible for reduced environmental impact, lower costs and improved recovery rates.

Key innovations to consider here are:

-

Automated sorting and robotics

Image Source: iStock/onurdongel

AI vision systems, robotics and automated conveyors separate device types and component classes faster and more accurately

-

Hydrometallurgy and low-carbon extraction

Image Source: iStock/wildpixel

New processes and greener chemical recovery techniques extract precious metals from circuit boards at room temperature and with lower emissions

-

Advanced mechanical recycling and eco-design tools

Image Source: iStock/Ivan Bajic

Better disassembly platforms, material traceability systems, and design-for-recycling guidelines allow manufacturers to plan for end-of-life processing beforehand

-

Digital traceability and circular marketplaces

Image Source: iStock/small smiles

Digital passports for devices and marketplaces for refurbished goods create liquidity for reuse and create audit trails that can be tracked by EPR systems.

How Companies Can End the E-Waste Problem: Step-by-Step Guide

Ending the e-waste problem means eliminating leakage so that all equipment goes through a circular and secure process. The goal is to maximize reuse, maintain responsible recycling, and protect sensitive data.

Here’s a step-by-step framework to end the e-waste problem.

Step 1: Build an Inventory, Standards and Partnerships

Create visibility, control, and a clear foundation for all e-waste handling.

-

Run a full asset audit

Track every device across all locations: servers, laptops, monitors, peripherals, storage media, networking gear, mobile devices, and IoT hardware.

-

Implement a unified e-waste policy (ITAD policy)

Analyze how old the equipment is reported, the process of hard drive sanitization or destruction, who approves decommissioning, and where devices are stored before pickup.

-

Select a certified disposal partner

Choose recyclers or destruction providers that meet:

- R2v3 or e-Stewards (environmental standards)

- NAID AAA for data destruction

- ISO 9001/14001/45001

- Verification closes the door to improper export and informal dismantling

-

Set up a secure collection system

Locked bins, cages, or tech rooms with chain-of-custody rules and access logs

-

Train employees

Explain what devices qualify as e-waste, how to report aging equipment, and what not to do (no trash disposal, no home removal, no unsanctioned resale).

Step 2: Scale Collection and Introduce Advanced Processing Options

It is important to make sure that devices consistently go through disposal channels, not drawers, closets, or unverified recyclers.

-

Launch scheduled enterprise-wide pickups

With quarterly or biannual pickups, you can make sure no buildup occurs and predictable workflows are implemented.

-

Deploy category-specific disposal workflows

For HDDs, wiping and shredding are common methods. If SSDs have to be disposed of or destroyed then go for shredding or crushing, monitors require specialized dismantling and IoT devices need secure decommissioning protocols.

-

Test advanced processing solutions

Wherever possible, integrate recyclers that use:

- AI-assisted sorting

- Hydrometallurgical metal recovery

- Low-emission processing methods

-

Collect detailed ESG and operational data

Request reporting on reuse rates, recycling yields, carbon savings and downstream vendors

-

Integrate remote-work collection programs

Prepaid return kits and secure packaging guidelines for remote or hybrid workers don’t miss out on assets.

Step 3: Adopt Digital Tracking, Advanced Data Destruction and Cost Optimization

Establish complete transparency and traceability including lowering the cost of IT assets.

-

Implement digital tracking or asset-level manifests

Use barcodes or RFID to track every device from decommissioning to transport and processing. Cover each stage until the final downstream destination.

-

Upgrade sanitization standards

Apply NIST 800-88 Clear/Purge/Destroy decision models for all storage media.

-

Optimize costs through device grading

Separate devices into re-sellable, refurbishable and recyclable only. This helps support higher ROI and less waste.

-

Perform internal audits

Review the chain-of-custody for assets and confirm that downstream vendors are certified.

-

Adopt digital reporting dashboards

Work on quarterly ESG performance, track recovered metal values, compare how the reuse vs. recycling split, and monitor emissions avoided.

Step 4: Strengthen Sustainability Reporting

Shift from disposal-first to reuse-first ecosystem and incorporate ITAD outcomes into sustainable strategies.

-

Create an internal reuse marketplace

Reassign functional devices between departments before purchasing new ones.

-

Work on refurbished equipment procurement

Use certified refurbished devices for non-critical teams, reducing emissions and cost.

-

Build channels with your processing partner

Provide device passports (age, specs, repair history) to increase resale value.

-

Expand sustainability reporting

Track E-waste diversion rates, weight and value of materials recovered as well as carbon footprint reductions.

-

Train procurement teams

Include recyclability, repairability, and disposal fees in the total cost of ownership when buying new hardware.

Step 5: Maximize Recovery and Maintain Continuous Improvement

Replace export-heavy disposal models with domestic or certified processing. This will help you achieve high recycling and reuse rates.

-

Commit to near-zero landfill policy

Make it part of your sustainability pledge and vendor requirements.

-

Use processors with advanced recovery capability

Make sure that all partners use mechanical and hydrometallurgical methods for maximum material extraction (gold, copper, palladium, rare earths).

-

Negotiate long-term contracts

For refurbished resale and material recovery, businesses need to stabilize costs and support consistent ESG performance.

-

Standardize cyclical device refresh

Plan your disposal by aligning refresh cycles with scheduled e-waste pickups to prevent stockpiling.

-

Benchmark results annually

Track key metrics such as:

- % of e-waste formally processed

- % recovered materials

- % reused/refurbished

- Cost savings

- Emissions avoided

- Compliance incidents (target: zero)

Case Study

A national retail chain with 200+ locations had no standardized disposal workflow so old devices piled up in storage rooms, risking data exposure and wasted asset value.

Challenge:

There were thousands of retired devices scattered across remote sites. The business had no audit trail, no chain of custody, and no consistent wiping procedure. It meant a high risk of data leaks from un-sanitized drives.

Solution:

They partnered up with a certified ITAD service and introduced quarterly scheduled pickups across all branches. With that, the company also implemented asset tagging and centralized reporting to track movement from store to processing facility.

Case Study 2

When a fast-growing AI software development company found that their headcount had increased in two years, they had to look at the trail of e-waste generated. Large volumes of laptops, phones, and development devices had piled up.

Challenge:

Hundreds of untracked, data-bearing devices created a security exposure. At the same time, procurement costs increased as older but functional devices were discarded. The company also did not have visibility into lifecycle emissions (Scope 3).

Solution:

They created an internal device marketplace to redeploy equipment to new employees. The company outsourced device sanitation and formalized a certified refurbishment workflow to help make sure that each device was sanitized and graded.

Case Study 3

It was detected by a large manufacturing plant that their e-waste was not being managed and disposed of smoothly. They replaced industrial electronics that included PLC boards, sensors, UPS systems, and drives regularly. Scrap handlers were informally removing old units for resale.

Challenge:

They realized that high-value electronics entered informal markets and there was zero transparency into downstream recycling practices. The company was liable to potential legal issues due to unverified data destruction and environmental harm.

Solution:

One of the most important changes the company implemented was establishing secure, locked collection zones for all retired electronics. They also enforced vendor access controls, restricting pickup to trained, authorized recyclers.

E-waste as a Green Economy Opportunity

If handled properly, e-waste can create substantial local employment across collection, sorting, repair, refurbishment, logistics and materials recovery. Analyses show that recycling creates far more jobs per tonne than landfilling or incineration—making the sector a candidate for green-jobs programs.

To maximize benefits:

- Build local certified recycling hubs that meet environmental and occupational safety standards.

- Formalize small recyclers with training, certification and fair contracts to reduce informal, unsafe practices.

- Link refurbishment programs to digital inclusion initiatives—donate refurbished devices to schools or nonprofits.

This creates local livelihoods while preventing toxic informal recycling.

Practical actions for governments include:

- Implement EPR with variable fees (higher fees for hard-to-recycle products)

- Encourage reporting into a national registry with audits

- Create producer take-back targets and publicly disclose performance

- Pair EPR with incentives for local recycling investment (grants, tax credits)

4 Ways to Build a Circular, High-Value E-Waste System

Ending the global e-waste problem requires more than recycling bins or occasional take-back programs. It demands a full ecosystem approach that addresses economic development, enforcement gaps, data transparency, and coordinated action by recyclers and businesses.

Here’s what to consider to build a long-term e-waste system.

-

Consider E-Waste as a Green Economic Engine

When managed properly, e-waste becomes one of the most powerful job creators in the environmental sector. Unlike landfilling or simple incineration, formal e-waste recycling creates jobs across the entire lifecycle:

- Collection & logistics (urban, rural and multi-site pickup systems)

- Sorting & dismantling (skilled jobs that can be formalized and made safe)

- Repair & refurbishment (extending device life while reducing procurement costs)

- Hydrometallurgical and mechanical recovery roles

- EPR compliance, data management, and reporting

Research shows recycling creates several times more jobs per tonne than landfill or waste-to-energy systems. Examples like Odisha, India demonstrate that scaling certified recycling infrastructure can generate thousands of full-time jobs. This is proof that a well-funded recycling ecosystem boosts local economies while preventing unsafe, informal processing.

Key actions to maximize socio-economic benefits:

- Build certified, compliant recycling hubs with proper environmental and occupational safety systems.

- Transition informal collectors and dismantlers into the formal sector via training, onboarding, and fair contracting.

- Link refurbishment programs with digital inclusion initiatives, enabling refurbished devices to reach schools, nonprofits, and underserved communities.

- Encourage businesses to donate or redeploy sanitized devices internally before sending the rest for recycling.

This model prevents pollution and supports economic uplift, making e-waste a pillar of the green economy.

2. Close the Enforcement Gap

Even with certifications and EPR frameworks, a major obstacle remains: illegal e-waste exports. Investigations have exposed millions of tons shipped to Southeast Asia and other regions under false labels (‘used electronics,’ ‘reusable goods’), overwhelming local infrastructure and feeding unsafe informal recycling.

Without strong enforcement, even the best-designed systems fail, making the enforcement gap one of the most pressing barriers to ending e-waste.

Key interventions needed:

- Strengthen customs and harmonize waste codes across regions to prevent mislabeling.

- Require digital manifests and “cradle-to-grave” tracking for all cross-border shipments.

- Publish transparent registries of exporters, recyclers, and inspected shipments.

- Impose meaningful penalties for non-compliance, especially for repeat offenders.

- Support receiving countries with grants and technology to scale safe disposal capacity.

Ending waste colonialism requires global vigilance, monitoring, and international cooperation.

3. Measure Progress with Data and Tracking

A circular e-waste system cannot emerge without consistent, verified measurement. Both countries and corporations must track their e-waste footprint with the same rigor applied to carbon accounting.

Why measurement matters:

- Many countries can only estimate their e-waste generation.

- Global formal recycling rates remain far below total waste generation.

- Companies often lack visibility into their take-back, reuse, and recovery performance—limiting ESG reporting accuracy.

Key tools:

- National recycling targets, published annually with independent verification.

- Corporate disclosures on take-back program performance, device reuse and refurbishment volumes, material recovery rates (gold, copper, aluminum, rare earths)

- EPR producer registries with public dashboards showing compliance, performance, and penalties

- Digital product passports with repair history, component data, and traceability information.

Data is the bridge that connects policy with accountability and that leads to real-world impact.

4. Follow an Action-Oriented Roadmap

Solving the e-waste crisis requires synchronized movement across all stakeholders. Below is a practical, high-value roadmap combining current best practices, policy insights, and implementation strategies from major regions.

For Governments and Regulators

- Implement or enhance EPR laws with variable fees that reward repairability and recyclability.

- Fund recycling infrastructure, robotics automation, and hydrometallurgical R&D.

- Build customs capacities to stop illegal shipments and inspect containers.

- Mandate repairability labels and design-for-disassembly requirements.

- Offer tax credits, grants, and incentives for certified recycling facilities and refurbishment centers.

- Create public dashboards showing collection rates, recycling outcomes, and producer compliance.

For Manufacturers/Retailers

- Adopt modular, repairable product designs with standardized components.

- Guarantee spare parts availability and accessible repair instructions.

- Launch consumer-facing take-back and buy-back programs with transparent reporting.

- Use digital product passports for lifecycle traceability.

- Partner with certified recyclers and publish end-of-life performance metrics.

For Recyclers and Technology Providers

- Invest in advanced mechanical and chemical recovery systems to improve yield.

- Expand automation through robotics, AI-based sorting, and smart logistics.

- Formalize small collectors into the legitimate supply chain through training and certification.

- Provide full downstream transparency, including vendor lists, material recovery rates, and audit-ready data.

- Participate in national EPR programs as verified, professional recycling partners.

For Businesses and Institutions

- Require suppliers to meet repairability and recyclability benchmarks.

- Embed take-back and recycling clauses into procurement contracts.

- Use certified ITAD partners for secure data-bearing-device disposal.

- Publish disposal and recovery metrics in ESG and corporate sustainability reports.

- Run employee collection drives, community drop-off events, and reuse programs (internal marketplaces, donation channels).

- Educate staff on storage, handling, and downstream risks to prevent informal disposal.

The Circular E-Waste System Framework (Stakeholders → Actions → Impact)

| Stakeholder | Key Actions | Direct Impact | Long-Term Outcome |

| Governments and Regulators | – Implement EPR with variable fees – Fund recycling infrastructure, R&D, robotics – Strengthen customs enforcement & harmonize waste codes – Mandate repairability labels & audits |

– Higher formal collection rates – Better compliance – Fewer illegal exports |

– A national circular e-waste system – Reduced environmental leakage |

| Manufacturers and Retailers | – Design for repair/disassembly – Ensure spare parts availability – Launch take-back & buy-back programs – Use digital product passports |

– Increased repair & reuse – Lower material loss – Transparent lifecycle tracking |

– Lower production footprint – Stronger ESG performance |

| Recyclers and Tech Providers | – Invest in automation & hydrometallurgy – Formalize small collectors – Provide downstream reporting |

– Higher recovery yields – Reduced worker exposure – Verified recycling streams |

– Scalable, compliant infrastructure – More green jobs created |

| Businesses and Institutions | – Use certified recyclers/ITAD – Require repairability in procurement – Publish disposal metrics – Run employee & community drop-off programs |

– Lower data and legal risks – Better reporting & compliance – Higher reuse internally |

– Organization-wide circularity – Lower Scope 3 emissions |

| Citizens and Employees | – Participate in take-back programs – Avoid informal recyclers – Extend device lifespans through repair |

– Cleaner waste streams – Lower device contamination |

– Stronger community participation – Reduced informal rec |

End your E-waste Problem Now!

Organizations that adopt structured disposal frameworks and build partnerships with certified e-waste pickup services can end their e-waste problem efficiently. So work with a nationwide partner to reduce the risk, cut costs, and improve sustainability performance. No matter if you manage a small office or a national network of facilities, the path is the same.

You also need to track your assets, prevent informal disposal, sanitize all data-bearing devices, and channel every item into a compliant recycling or reuse stream. By taking these steps today, businesses not only protect their brand and the environment but also lay the foundation for a cleaner, more resource-efficient future.

FAQs

1. What is the single most effective way to reduce e-waste at scale?

The most impactful way is Extended Producer Responsibility (EPR). This is a policy that shifts financial and operational responsibility for end-of-life electronics back to manufacturers. It drives investment in recycling infrastructure, makes repairable products cheaper to produce, and dramatically increases collection and recycling rates. But EPR works best with business participation, consumer awareness, and certified recycling systems.

2. Why does illegal export remain such a major barrier to ending e-waste?

Enforcement gaps allow mislabeling, fraudulent declarations, and informal brokers to ship broken electronics to countries with weak processing capacity. These shipments fuel hazardous informal recycling and pollution. The solution requires stronger customs systems, digital shipment manifests, harmonized waste codes, and public registries. When these tools are active, illegal exports drop significantly.

3. How can businesses directly help end the e-waste problem?

Businesses play a powerful role by adopting certified disposal, choosing repairable products, and building internal collection and reuse systems. This includes using certified ITAD providers, requiring repairability and recyclability, logging devices across all locations, and ESG reporting. When companies adopt a circular lifecycle strategy, they cut emissions, reduce data risks, and significantly increase formal collection volumes.

4. What role does technology play in solving the global e-waste crisis?

AI-driven sorting robots, automated dismantling lines, hydrometallurgical metal recovery, digital product passports, and traceability systems all help increase recycling yields. These innovations also make e-waste processing safer for workers and more economical, allowing local recycling industries to grow instead of relying on exports. When combined with strong regulatory frameworks, technology leads to circularity.

5. Does solving e-waste really create jobs and economic benefits?

Yes, formal recycling and refurbishment create far more jobs per tonne than landfilling or incineration. Collection, sorting, repair, refurbishment, logistics, and materials recovery all generate stable green employment. Regions that build certified recycling hubs gain new technical roles and can integrate small informal recyclers into safer, regulated supply chains. This not only reduces pollution but also boosts local economies while supporting digital inclusion programs through refurbished-device donations.

Leave a Reply